Certified Manufacturing

Jade Roller & Gua Sha craftsmanship is not an easy job. We would like to be as transparent as possible for you and are happy to tell you more about our manufacturing.

How Jade Skin Care and Beauty Products Are Made

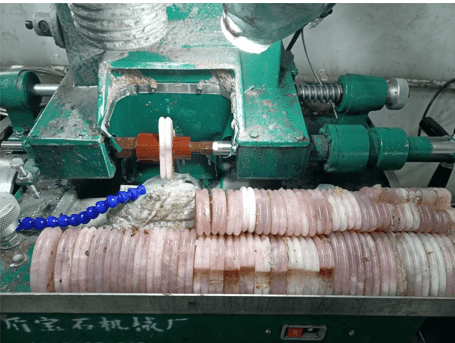

facility is located in a growing region of Huizhou, China, well-equipped testing facilities and strong technique. Production quantity exceeds 10,000 pieces per day. Based on the modern facility factoryand experienced know-how team, our jade roller & Gua sha board production is intended for the premium end of the beauty, massage, gift and cosmetic industry.The manufacturing of completed jade gua sha roller and tools comprises a number of stages. They include raw material –cutting–hand cutting–hand cutting in square shape– shape stone–polishing–sem-finished products- assembly- stone accessories-finshed goods-packing — finished goods packing. All these procedures need to be double checking to make sure the quality product can meet the clients requirement and exceed their expectation.

Full Capacity in Our Jade Roller & Gua Sha Manufacturing Plant

200+

– Instock styles –

the foremost advantage of stocking a huge amount of molds in-house is the flexibility. One factory can hardly meet all your requirements.

10000+

– Pcs daily production –

React to market quickly. Our bulk production allows businesses to move through production phases quickly and easily.

8

– Production lines –

Completed production lines from raw materials to the completed products with the completed quality control.

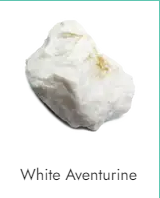

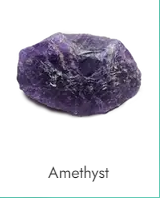

The stone materila we can provide

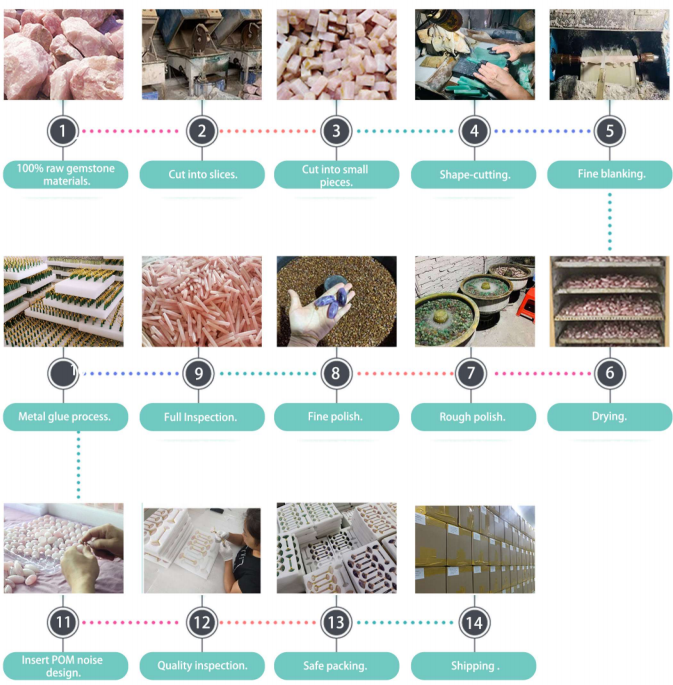

Jade Roller & Gua Sha Production process

A jade roller you buy needs to go through all these steps, so what you buy is not only a jade roller, but also the efforts and dedication of our production workers.

How many steps does it take to make a jade gua sha board?

In fact, the steps to produce a gua sha board and a jade roller are the same, both have to go through the process of selecting the original stone>cutting the stone> hand-painting the pattern> cutting the pattern>high-pressure shaping

RoHS, SGS…We Strive to Make the Best Jade Massage Roller and Nature Skin-care Tools for You

Quality is not a coincidence. Our quality management system includes the certification according to SGS and RoHS. We daily ensure the quality working of our processes, from the delivery of raw material to the packaging of our products. This is in our very own DNA and this is why we work with global brands to make their products qualified.

Click video to see how we call ourselves the Jade Roller & Gua Sha Tools manufacturer:

“There are more than 100 different styles of jade rollers. Besides rose quartz, amethyst and green aventurine. We have more than 30 different Crystal&Gemstone materials which are 100% natural. It can be customized according to the needs of customers.

INSTOCK Jade roller & Gua Sha

50~

Over 50 jade roller and Gua Sha styles in stock to meet your instant purchase.

CLIENT RATINGS

99%

99% satisfaction of our clients and high repeat purchasing rate.

EXPERTISE

10

10 years of experience in Gemstone manufacturing and packaging.

Reference

https://starseedmakeup.com/about/”

Superior Craftsmanship in 17 Steps

Unveil few steps out of our 17 processes. Feel free to get our catalog to discover how MystGem manufactures your Beauty tools and nature stone massage devices

Discover Our Quality Management

Our quality policy is built on the concepts of quality control and quality assurance. We are affiliated with multiple quality management organizations and our operations are ISO certified.

Imported 100% Natural Stone Materials

We build the good relationship with the imported raw materials supplier, honestly, the nature materials which we the real premium quality will obtain 80% and the low quality will be waste the rate 15-30% which can not meet our requests;

Raw Stone Material cutting and shape drawing

Cutting the raw jade & gemstons into pieces. The intelligent control system replaces the traditional control system with a large number of switch buttons, thus greatly reduse the fail rate in the working process. The computer intelligent control system can automaatically display when there is a fault, so as to reduce the trouble of trouleshooting.

Cutting In Square Shape

Cut large jade & gemstone into small pieces. Stable cutting, low noise and safety.

Shape Engraving Stone

Processing various shapes of gemstones. Uniform size and shape, high precision. It is widely used in the forming and processing of stones, jade, semi-precious stones, wood, shells, fossils, ivory, and other materials.

Clean & Polishing

Suitable for all kind of gemstone polishing processing widely used in gemstone, semi-precious stones, jade, agate, white jade, topaz, crystal, glass, shells, handcrafts. The whole piece of steel plate is used as the bucket bottom to ensure that the density distribution of the whole machine is uniform, the capacity is large, the overturning is good, and the polishing efficiency is high.

Drying Stone Accessories

Need to be High temperature disinfection and drying, make the roller head and handle’s surface smoothly.

Assmebling

Use the hareware to install the roller and handle, make it more beautiful and work smoothly.

Packaging

Private label logo customized jade roller tools. We can put your logo on the jade roller to advertise. it can help brand promotion, Personalized customization, including product redesign and packaging design, to meet the various needs of customers. ”